"My father started the business, by making carts, wheels and joinery in 1955," says Jože Kenda, who continued his father’s business and passed it on to his son Uroš a few years ago. Jože managed to establish a successful and solid company, which exports its entire production. In 2010, they carried out a major business deal for the American market. Their tables, bar stools from solid wood and wardrobes furnish 450 rooms in a prestigious hotel in Los Angeles and a global jewellery chain. They do not have to look for new clients at the moment since they cooperate with buyers from different countries. At the request of a particular client, they also successfully passed the international SMETA audit this year. In the 1970s, Uroš’s grandfather added a first combination machine to the home-made wooden tool. “At the time, the machine was as expensive as if you were to buy a yacht today,” remembers Uroš’s father Jože, who spent most of his childhood in his father’s workshop. To gain respect towards his craft, his father sent him to Cerkno to work as an apprentice. He later found employment in Lesna industrija Idrija and then he worked in Celes for many years. When the company faced its first crisis, Jože had already started his own business. In cooperation with other Slovenian companies, he started making tables for Ikea. “There were so many orders that we barely managed to keep up,” he remembers.

They do not look for clients; instead, the clients look for them

Three years ago, Uroš Kenda took over the company. He is proud of the production of top bar stools for the Scandinavian market. The client from Denmark first ordered stools in Slovakia and Malaysia. Because they failed to attain the prescribed quality, the production was entrusted to Kendales. The client is now pleased with the quality and occasionally visits their production facility. He highly appreciates their products, says Uroš. They have made 5,500 prestigious stools from solid wood, which reach extravagant prices on the market. The quality of their work speaks volumes. They do not look for clients but buyers from the USA, England and Scandinavia look for them.

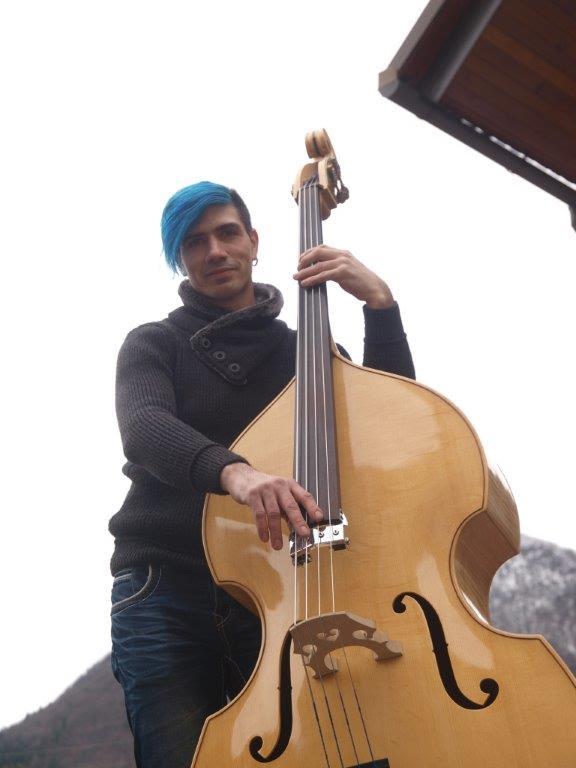

Two great loves: wood and music

Uroš combined wood and music, two of his greatest loves, into one. He visited a world-renowned producer of musical instruments in Milan to find the best wood for the manufacture of a double bass. A new business developed from his love of music. He invested at least 150 hours in the curving of the wood and manual labour on the bass. However, he did not stick to bass only. He has already shipped 35 wooden electric guitars to the USA. "High-quality products sell well in the USA since they have plenty of low-budget ones. Such guitars cost several thousand euros and are purchased only by serious musicians. Many order custom-made guitars. They tell us what kind of sound they want, and the master craftsman has to know how to attain that sound. He must be talented and possess great knowledge on how to correctly combine different types of wood. One guitar may be composed of three to four types of wood: spruce, linden, poplar, cherry, plum, beech, walnut, maple, mahogany, teak ... depending on what sound we want. Each guitar is thus unique."

Uroš, who looks more like a pop star than a businessman, is full of ideas and plans, but he nevertheless never forgets to mention the importance of the foundations which his father and grandfather laid for him. He says that the great advantages of their family business are a small size and fast adaptability to the requirements of the market. In the future, they will continue to focus on designer products with higher added value. "The design of the current Kendales products is mainly determined by the clients, but one day, the products of our brand will come to the fore as well. I have many ideas, which I will realise after production at the new location starts, plans which will simplify work for nine permanently employed workers," he stresses. He is proud of his hard-working and well-qualified workers. The production for the next year has already been planned and the products sold. But the quality always comes first. "Contracts with clients are not so important any more. We know that if our products lack quality, we won’t get a new order. The price has to be just right too. It must cover the costs of our work accordingly, and beyond that, we mustn't care at what price our products will be further sold by the client."