You are the youngest shoemaker in Slovenia. Where were you educated?

I graduated in original design of hand-made shoes from the Faculty of Natural Sciences and Engineering, which makes me a graduate shoemaker. I am still the youngest shoemaker in Slovenia, since the secondary school for shoemakers closed down 15 years ago. After I finished my secondary education, the school was closed down due to lack of interest in this profession.

Was this your childhood dream?

As a small boy, I accompanied my father in the Nama department store, where he repaired shoes. I saw it as a good opportunity to continue the tradition. But I also wanted more than the classic black shoes that my father made for my first communion. I took them off immediately after the photos were taken and put on trainers. I wanted something more comfortable, different; shoes that would stand out.

When did you make your first pair of shoes? Do you still wear them?

Yes, they are still in the wardrobe and I wear them once or twice a year. I made an elegant i.e. derby model from box calf, combining black and red. I made it when I was 15 in the first year of secondary school in practical training. For my diploma thesis, I made unique shoes from common sole and kangaroo, with dice in the heel. The idea came from everyday life, from playing Ludo.

What about women’s shoes? Did you make men’s shoes first?

No, it went parallel. I first made comfortable shoes for my mother, who had problems with foot bones, then a more elegant pair for my little sister. It was first for relatives and then for others.

What is your favourite pair of shoes?

I have three or four pairs that I wear, and then I change them all together, e.g. once a year. So, I have a favourite pair every year.

What is the process of manufacturing?

A client calls me and we schedule a meeting. Some clients already know what they want and some leave the decision to me. Women usually know what they want and combine the shoes with a purse or a dress they have. Men more frequently leave the decision to me and then are very happy. They tell me only what they will be using the shoes for. Reasons vary: for everyday use, for driving, walking, special occasions, and similar. I try to fully adjust to the clients when I select the material, the colour, etc. The first condition is that the shoes should be comfortable and then also that they are different. The shoes are made to fit the foot in length and width. For women’s shoes, I try to make the heel as comfortable as possible.

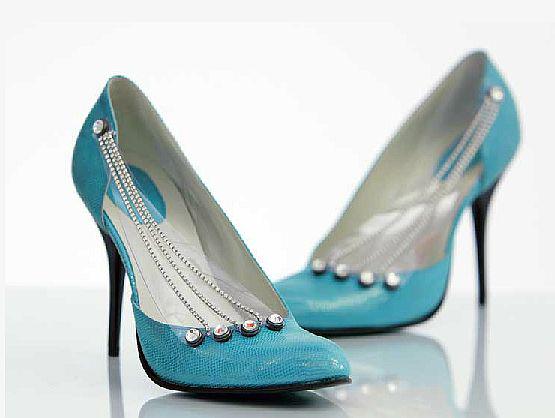

What kind of woman wears your shoes?

A woman who dares to be a little different, is bold. In that sense, I am proud of my clients, I have to stress this. When they come and see me, they want black shoes, for example, but they leave with purple ones. And almost always they return to get another pair, for example, red. I have also noticed with men that they are very happy with a somewhat out-of-the-ordinary purchase. They are looking for black or brown shoes, and I make them a pair of grey or purple ones. And then they return and say, “I have never received so many compliments as I have about your shoes.”

Your models are extravagant and unique, but you also provide comfort.

In my work, I combine knowledge from the shoemaker’s school and university, including the experience I have obtained at Milan and Bologna fairs. The manufacturing must involve not only aesthetics, but also comfort, I am certain of that. I make an anatomically formed sock, 5 mm thick, heat it up and model it according to the client’s weight and the shape of the foot, so the weight is evenly distributed along the entire sole. Then I wrap the sock in leather. After a long night of dancing, you will still have a smile on your face – guaranteed (he laughs).

What materials do you use?

The emphasis is on leather, particularly exotic leather. I use crocodile, python, ostrich, frog, fish and other leathers. I buy materials in Italy, with farming certificates, not caught in the wild. I also use Swarovski crystals, lace from Idrija, knitwear, fur; I am happy to consider clients’ wishes and add to the shoes what the clients want. Sometimes they bring things with them. I also use technical materials, such as for example ‘ledra’, which is a type of artificial leather, antistatic, antibacterial, suitable for allergic people, extra-strong leather resistant to bacteria and chemicals. I make most of the shoes from leather, but I adjust to the client.

How long does it take to make one pair?

About 15 to 20 hours, depending on how difficult it is. It takes about 14 days for the client to get their shoes. But I try to finish them in 10 days. I usually make them to order, but I also showcase them so the clients can see the make and can also buy those.

You are known for your innovations. Where do you find your ideas?

I usually get ideas from everyday life and then incorporate them into the shoe. For example, I got the idea for shoes with carbon from carbon skis and bicycles. Carbon is six times thinner than steel and eight times stronger; so, I incorporated this and made unique futuristic shoes. The shoes with heels made of plexiglass containing mercury are also the result of an idea from everyday life. I also made shoes that you can charge a mobile phone on; it is possible to incorporate a USB flash drive or light into a heel. I also made women’s boots with a GPS device, so clients can track the location of the boots. I’m not kidding. There are actually no boundaries for me when it comes to designing shoes.

The Slovenian market has already recognised Mihoya products. Who are your clients?

People who want the best for themselves. When they see a product and try it on, they see the difference. My clients are usually satisfied enough to then become regular clients. Almost no one visits me just once. The clients come from all over Slovenia. I must say that I am really pleased.

What about foreign market?

I am preparing for a fair in Monaco (a fair of prestigious supercar brands – Top Marques Monaco) which will be held on 17 April, and that will be the perfect opportunity to present Mihoya shoes. I am cooperating with the automobile industry, i.e. the Slovenian company Tushek, which is showcasing its supercar TS 600 at the fair, hand-made by Aljoša Tušek himself. In addition to the car, which is worth over one million euros, the buyer will also be able to choose Mihoya shoes to drive the car.

Your wishes for the future?

For the clients to be happy and keep coming back.

Danila Golob, SINFO